On 20th September 2011, when the Stara Komenda brewpub opened its doors, Szczecin finally lost its status as “Last major Polish city without a brewpub”. Since then, three beers are regularly on offer in the Komenda’s bar: a wheat, a light beer and an amber; and sometimes the visitor can find a seasonal or special beer, for example a smoked beer (“Rauchbier”), a black beer (“Schwarzbier”) or a Bohemian style dark beer. All of these enjoy great popularity among the guests.

On 8th July 2012, the young owner and head brewer of the Stara Komenda, Damian Kunach, dared to take an experiment and invited me to brew an ale, a top-fermented beer, on his brewing plant; he planned to offer this as one of the specials. After lengthy discussions and careful weighing, we decided on an American Pale Ale – strongly, but not overly hopped, light, tangy and aromatic. Based on Pilsener malt, with a hefty dose of “Hallertauer Tradition” from the Spalt provenience as the base hops, and with a lot of American “Willamette” as flavouring hops for an earthy, grassy and equally fruity note. Dry yeast for fermentation should be the Fermentis US-05.

Sunday started early – already at eight o’clock we stood at the malt mill and ground the malt, then we reprogrammed the Kaspar Schulz plant according to my mash scheme, and then we started the mashing process. As this programme ran automatically, we used the time to clean and disinfect the fermentation vessels and cleaned in one go the dispensing systems – after all, the first regular guests are expected to drop in around noon. When we pumped the mash from the mashing vessel to the lauter tun, the restaurant awoke slowly to life. The cleaning ladies dropped in, a moment later the cook showed up, and finally the barmaid, and whilst the lauter process was still ongoing, the tap room filled with the first guests – just a normal everyday’s experience in the brewpub.

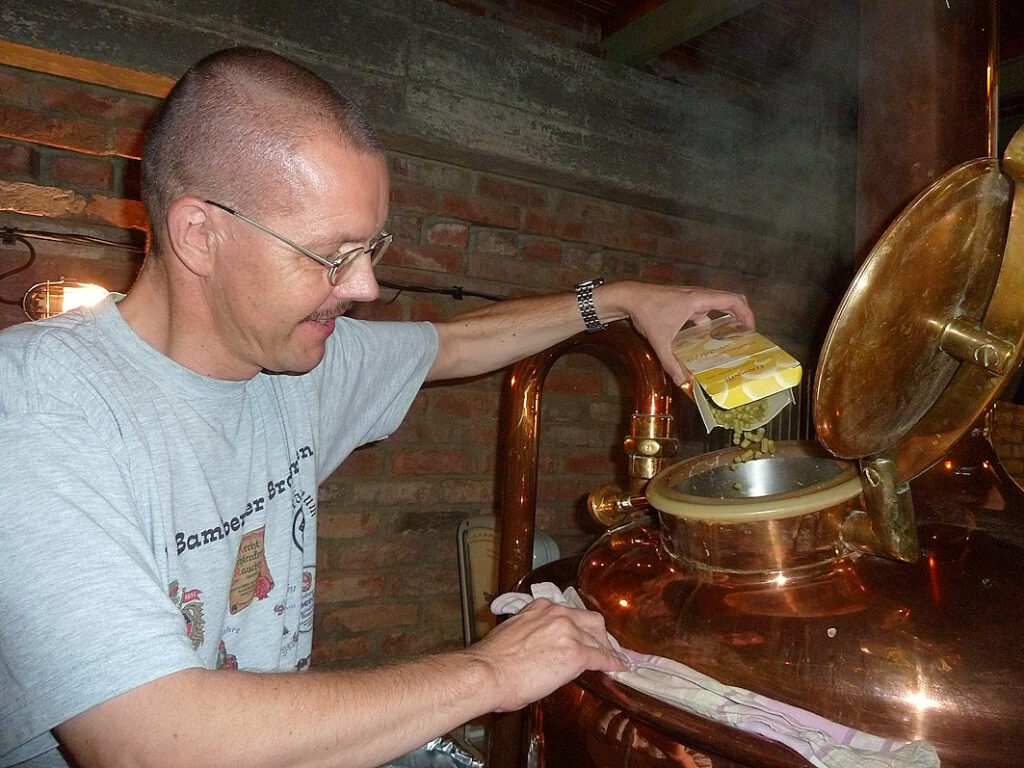

the author adding hops

When we checked the gravity for the first time, we were surprised that the yield was higher than expected – the wort showed about 14% of original gravity. In order not to cross the tax class limit, Damian has to brew the second batch tomorrow a little thinner – both batches will be mixed in the fermentation vessel.

Next step was to clean the lauter tun from the spent grains, and then it was time for a break and a hearty lunch. Whilst the wort was boiling and the vapours draught gently through the brewery, there was time for a first résumé: Brewing on a professional plant is significantly less work than at home with the electric cooker – but it is just as much of fun. Although much is completely automated, there are much more parameters to control, and many things to observe that do not play a role at home.

Finally, we pumped the wort through the plate cooler into the fermentation vessel and opened the large brick of dry yeast. Carefully, I spread it over the cold wort. A last time, we cleaned the Kaspar Schulz plant and flushed every single pipe thoroughly. For today, the work was done. For me as a pure amateur brewer, it was a nice experience, and now, we just have to wait, whether the beer in fact will taste the way it ought to.

Stara Komenda Browar

Plac Batorego 3

70-207 Szczecin

Poland

Hinterlasse jetzt einen Kommentar